Pneumatic double - station heat press machine

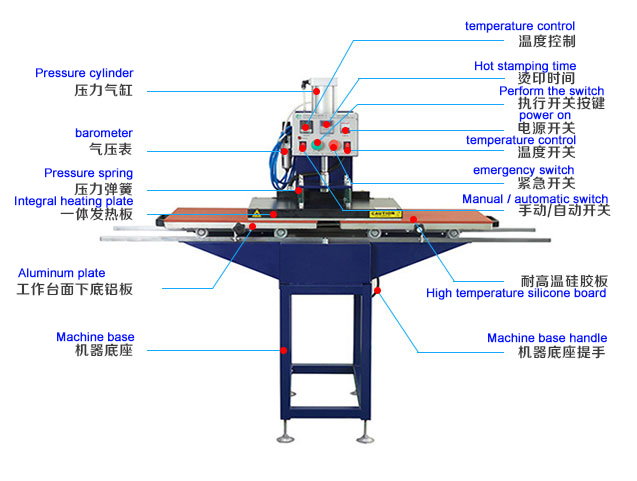

1. High quality aluminum heating plate, electric heat pipe and plate body pouring into a body, heat transfer fast, hot and uniform, energy conservation and environmental protection.

2. Single table integrated temperature control, automatic electronic timing, complete automatic warning sound.

3. Adopt mechanical electrical components, imported pneumatic components, precise and durable.

4. Digital display temperature control system, temperature control accurate (+ / - 1 ℃).

5. The workbench is pasted with high performance imported elastic foaming silica gel, soft and smooth without hardening.

6. Bilateral design, double station can improve work efficiency, the effect is better.

This machine has three modes, automatic, semi-automatic and manual. Using imported moters,imported components, small size, accurate security, high availability,long life.

Four rotary tables, it is more suitable for large output, it's the best choice of flowshop.

Digital display, intelligent temperature control, the error is ±1°C.

Digital time display, high accuracy Elegant and beautiful structure.

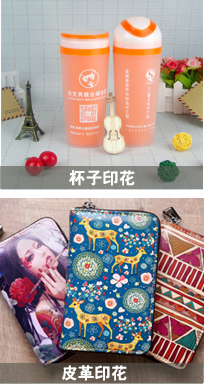

Hot stamping machine can be a variety of heat transfer pattern by thermal transfer or sublimation printing in the fabric, fabric, plexiglass and other materials on the machine, the machine all digital display, microcomputer control, high precision, the use of high-quality heating pad, With automatic temperature setting, automatic countdown delay time setting, the insulation state of time set, hot stamping a variety of different diameter materials.

Applications: clothing, backpacks, scarves, ties, home textiles, ceramics, mouse pad, metal pendants, travel caps, cups and so on.

|

|

|

|